Design/3D Modeling

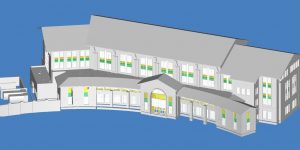

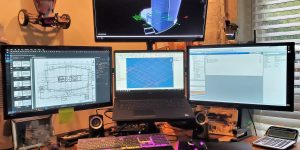

We create significant value for our customers through our in-house and outsourced capabilities and internal control of the design and drafting process. These services are best utilized when we can engage early during the planning process of a project where we can combine our significant industry experience and VDC capabilities.

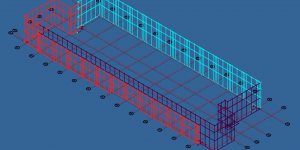

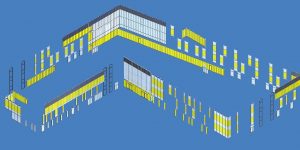

Virtual Design and Construction (VDC)

VDC is the management of integrated multi-disciplinary performance models where the design is constructed with computer-based performance models that contain all components of the project. This is typically done using a combination of AutoCAD, Revit, BIM360 and Inventor. Inventor allows us to bridge the gap between design and fabrication while simultaneously integrating with CNC programming. This facilitates a integrated, seamless process providing greater accuracy and time-savings, adding value to the general Contractor and owner.

Why is 3D modeling becoming a Dynamic Glass’ standard operating procedure?

To Add VALUE to our clients by delivering better projects through the following benefits:

A project does not have to be BIM coordinated to benefit from the efficiency and improved accuracy of VDC. Dynamic Glass utilizes our extensive VDC capabilities specific to our glazing scope with a meticulous focus on accuracy and constructability to add value by consistently delivering accurate, consistent results.